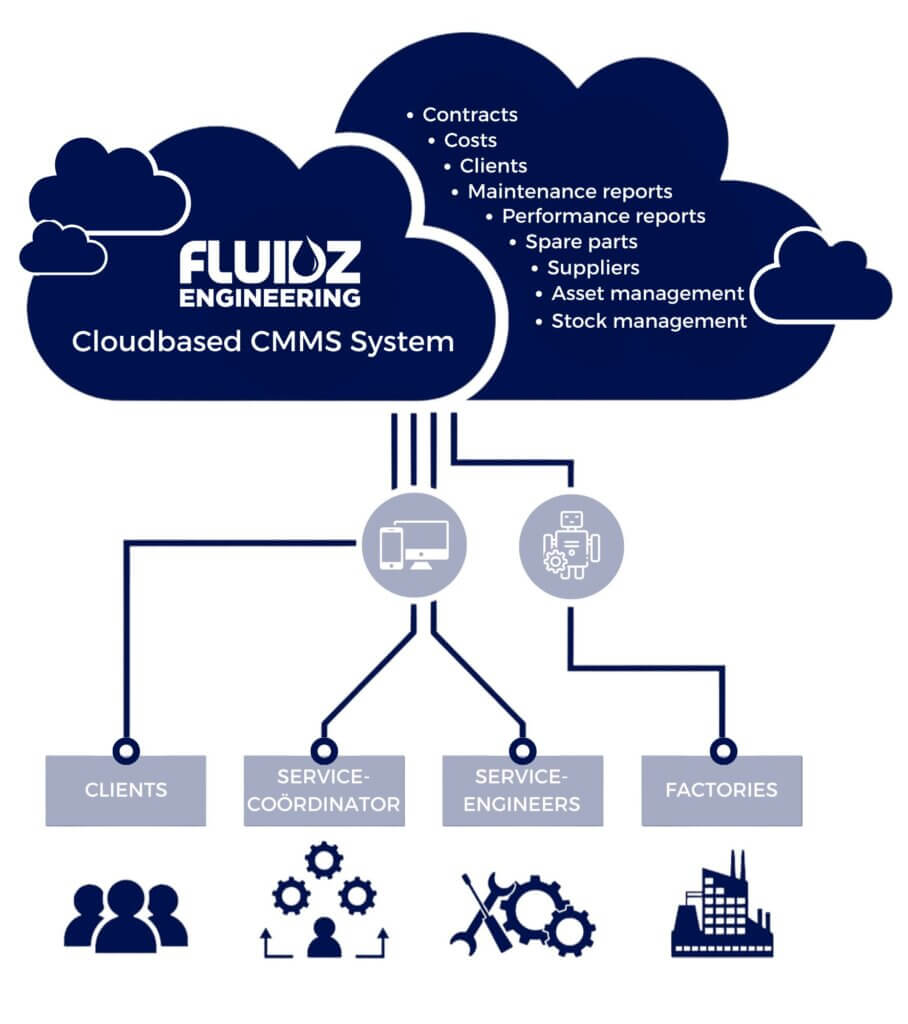

In our maintenance plans, we assess the following, among others:

- What are the critical process and/or machine parts?

- What are the critical spare parts?

- What is the use of the installation (24/7, 16/5, 8/5)

- Wat is de gewenste OEE (Overall Equipment Effectiveness)

- Is there a high thermal load?

- Is there a high mechanical load (abrasiveness)

- What is the vulnerability of your products?

- What are the critical points of your installation?

- What is the structure of your installation?

Based on this information and the technical documentation, we draw up a maintenance plan. This maintenance plan looks at the inspection frequency for each specific component. We also look at the necessary revision frequency per part. We make a distinction between product contact parts and non-product contact parts.

From this maintenance plan, the inspection and maintenance plans are distilled. These plans are evaluated annually and adjusted where necessary.

Would you like to know more about our maintenance plans? Get in touch with us.