Discover the Inline Pasteurizer

Want to know more about the iPAS? You can find all the information in the brochure.

Are you looking for an efficient and reliable method to increase the safety and shelf life of your products?

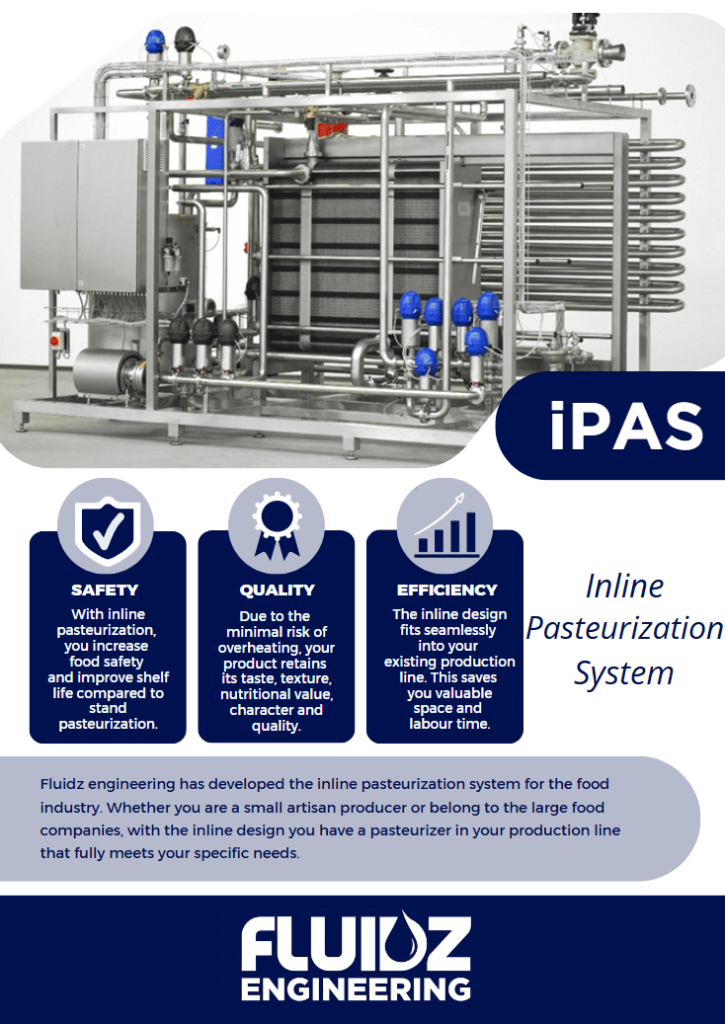

With the integration of an Inline Pasteurizer (iPAS) in your production process, you can pasteurize a wide range of foods.

Whether you are a small artisan producer or a large food producer, inline pasteurization focuses on your specific needs and helps to market your products with quality and assurance.

Want to know more about the iPAS? You can find all the information in the brochure.

Fill in your details below and receive the brochure in your mailbox within minutes.

The Inline Pasteurizer eliminates harmful micro organisms in a completely controlled process. In addition, the iPAS is equipped with a number of safety systems, such as a double pasteurization temperature recorder and pressure monitoring on the various heat exchanger sections. As a result, you minimize the risk of food-related diseases and we guarantee product quality and safety at all times.

Due to the controlled conditions, the temperature is consistent. This extends the shelf life and reduces waste.

Unlike traditional pasteurization methods, inline pasteurization minimizes the potential for overheating, preserving the flavor, texture, and nutritional value of your products.

Thanks to its inline design, pasteurization can be seamlessly integrated into your existing production line, saving you valuable space and labor time.

The temperature of the products is used to control the temperature. This saves you on energy costs and allows you to produce more sustainably.

Do you have a question or would you like advice? Call our colleagues on +31 85-5001767 or fill in the contact form above. You will always receive an expert answer.

The iPAS is a versatile system and is suitable for many liquid products:

Your product is leading in the composition of your Inline Pasteurizer.

We look at the pasteurization temperature, type of heat exchanger, holding time, cleaning and tool life.

Depending on the product features, we will work with you to put together the optimal configuration.

With the product features as a starting point, we equip your iPAS with a plate heat exchanger, tube changer or scraped heat exchanger. In the videos below you can see the different exchangers in action.

Plate heat exchanger

Tube changer

Scraped heat exchanger

The iPAS is equipped with an autonomous PLC control with touch panel. Via the touch panel, the operator can easily change settings and view the process progress.

The system is equipped with a logging function that stores the critical parameters per batch.

Do you want to communicate with other installations within your production process? The iPAS can do it! You can connect the Inline Pasteurizer via Profinet.

With the Inline Pasteurizer (iPAS) your product retains its quality

Specifications

Technical specifications can be found in the brochure.

Options

The components and equipment items of the iPAS unit are of the highest quality level (manufactured by Alfa Laval) and have EHEDG certifications.

Are you curious whether the advanced technology of the pasteurizers is suitable for your production process?

Please contact our advisors for personal advice on +3185-5001767 or via the contact form.

Or look for a CIP system that fits perfectly with your iPAS.

Does your production process require sterilization instead of pasteurization? Then take a look at UHT.