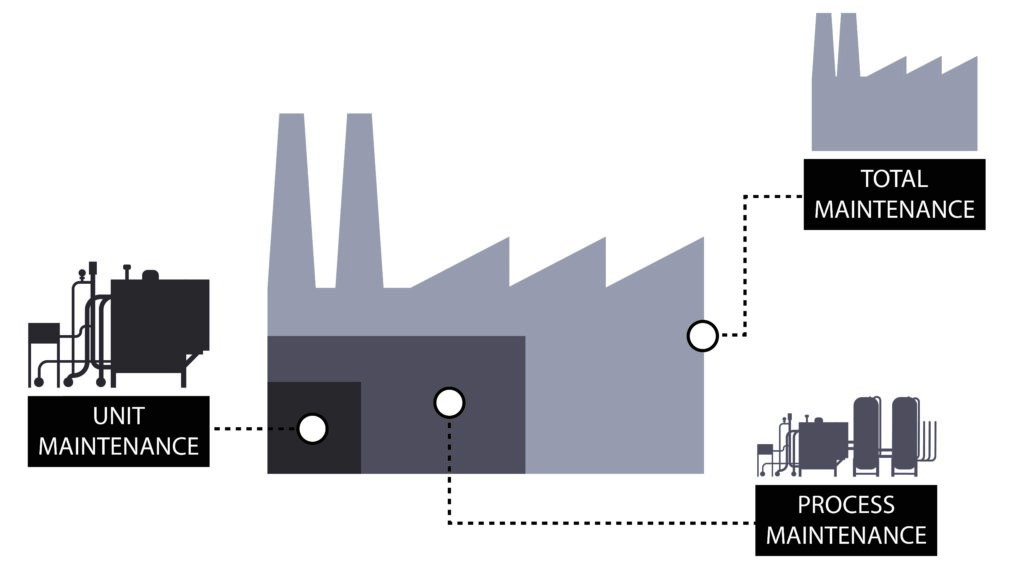

Maintenance methods

Unit maintenance

We maintain a specific process installation for you. To this end, we draw up an extensive maintenance plan, in which the availability of your installation is central. We make a distinction between critical and less critical parts of the process. Based on our Maintenance Plan, we carry out periodic inspections and periodic maintenance. All work carried out by us is recorded for you, giving you a complete picture of the condition and performance of your installation. In consultation with you, the maintenance plan will be adjusted to the specific needs of the installation in the future, based on performance and occupancy rate.

Process Maintenance

We maintain all your process installations. We draw up an overarching maintenance plan for this. Your complete machinery is put into the CMMS system by us, giving you a total overview of your entire machinery. The availability of your machinery is central to our maintenance plan. We make a distinction between critical and less critical process parts and installations. Based on our maintenance plan, we carry out periodic inspections and periodic maintenance. All work carried out by us is recorded for you, giving you a complete picture of the condition and performance of your installations and machines. In consultation with you, the maintenance plan will be adapted to the specific needs of the installations in the future, based on performance and occupancy rate.

Total Maintenance

If you are looking for maximum peace of mind, choose our total maintenance solution. We map out your complete production location. We map out matters such as process installations, process utilities, filling and packaging machines, means of transport, building-related installations, buildings and sites for you. We provide maintenance advice for all these matters.

Based on our maintenance plan, we carry out periodic inspections and periodic maintenance and, if desired, subcontracts specific maintenance matters or inspections (e.g. steam boilers, cooling systems, pressure tools, NEN3140). All work carried out by us and third parties is recorded for you, giving you a complete picture of the condition and performance of the entire production site. We take care of third-party planning and ensure that the maintenance process runs smoothly. In consultation with you, the maintenance plan will be adapted to the specific needs of the installations in the future based on performance, occupancy rate and replacement policy.

If the type of maintenance you want is not listed, please contact us. We are happy to provide you with tailor-made advice.