Optimal CIP Cleaning 1: Hygienic design

15 August 2025

Today we start with the 10 basic ingredients of optimal CIP cleaning!

Ingredient 1: The hygienic design

An hygienic design of a process installation is designed in accordance with the EHEDG guidelines.

Why is this important?

A food production installation must be able to be cleaned properly.

Visibly and invisibly.

Therefore, it is important to apply the following design rules:

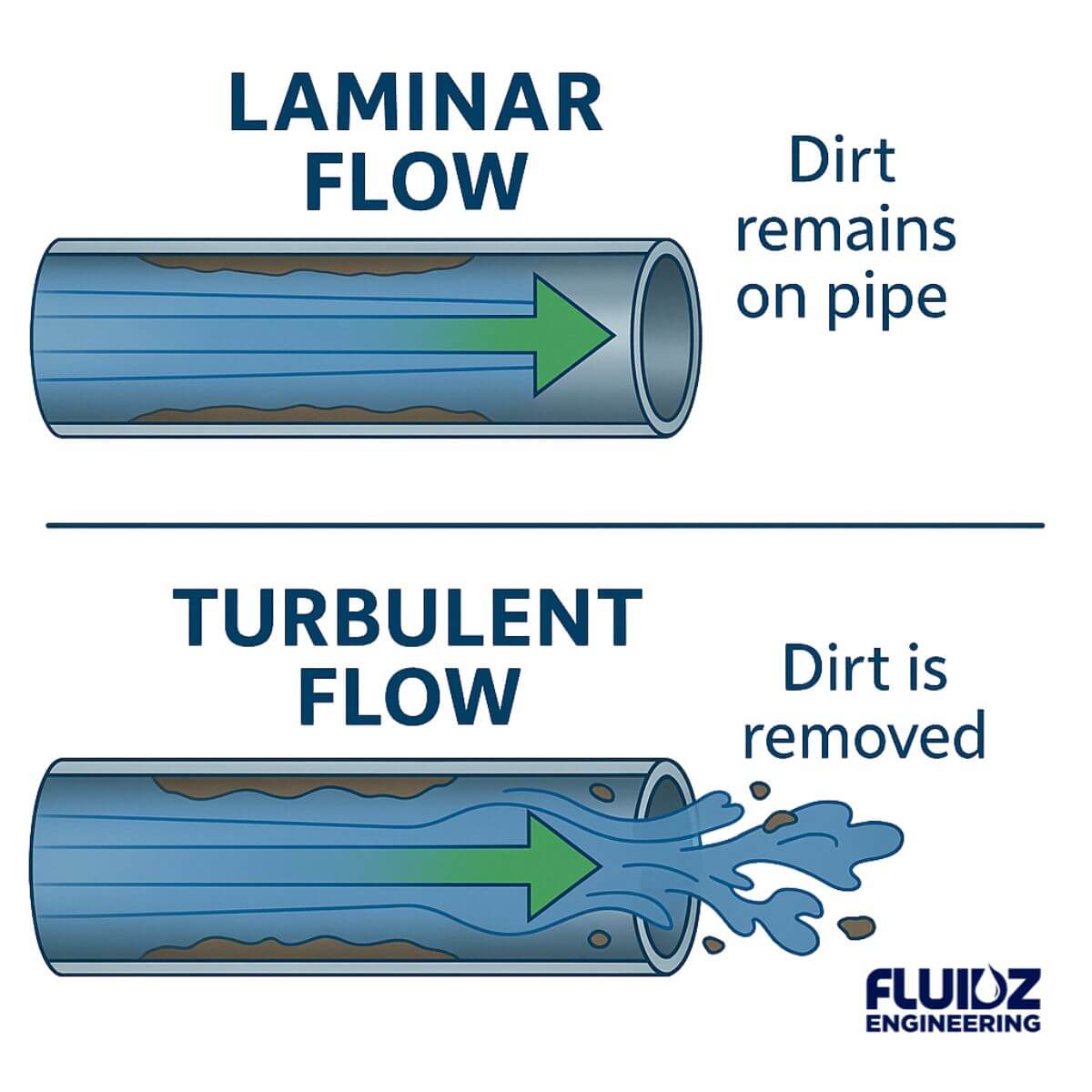

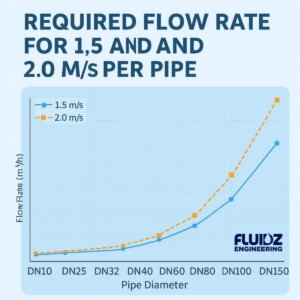

- Pipe velocity during cleaning: 1.5 – 2 m/s (=turbulent flow)

Tip: Note that velocities during cleaning are higher than during production- Figure Pipe flow: – Figure Pipe velocity:

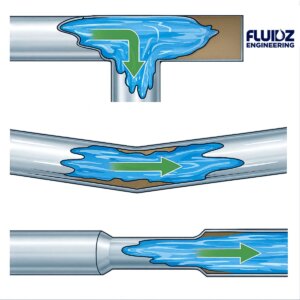

- Avoid pipe branches

Tip: Use flow-through branches (swept tees) instead of standard tees to improve cleaning. (<1.5D)- Figure Pipe dimensions:

- Avoid dips in the pipework, as dips increase the risk of bacterial growth and corrosion

Tip: Pay attention to pipe support

- Avoid diameter changes

Tip: If a diameter change is unavoidable, use gradual, conical transitions instead of abrupt transitions.

Use eccentric transitions in the horizontal plane.

- Avoid combining line and tank cleaning, as tank and line cleaning often have different flow, pressure, and cleaning time requirements

Tip: Design separate circuits for tanks and pipes

- Design the pipework to be fully drainable by means of a slope and, if necessary, drain points

Tip: Design pipes with a slope to drain points (0.5–1%)

- Ensure good full flow and drainability of pumps and heat exchangers

Tip: Choose pumps and heat exchangers with hygienic design certifications (EHEDG, 3-A)

- Know the (cleaning) specifications of the equipment (cleaning flow or pressure) and adjust the piping accordingly

Tip: Record these values in the validation protocol

This information, along with additional explanations, will soon be available on the FAQ page of our website.

Next week, we’ll explain ingredient 2: Material selection.