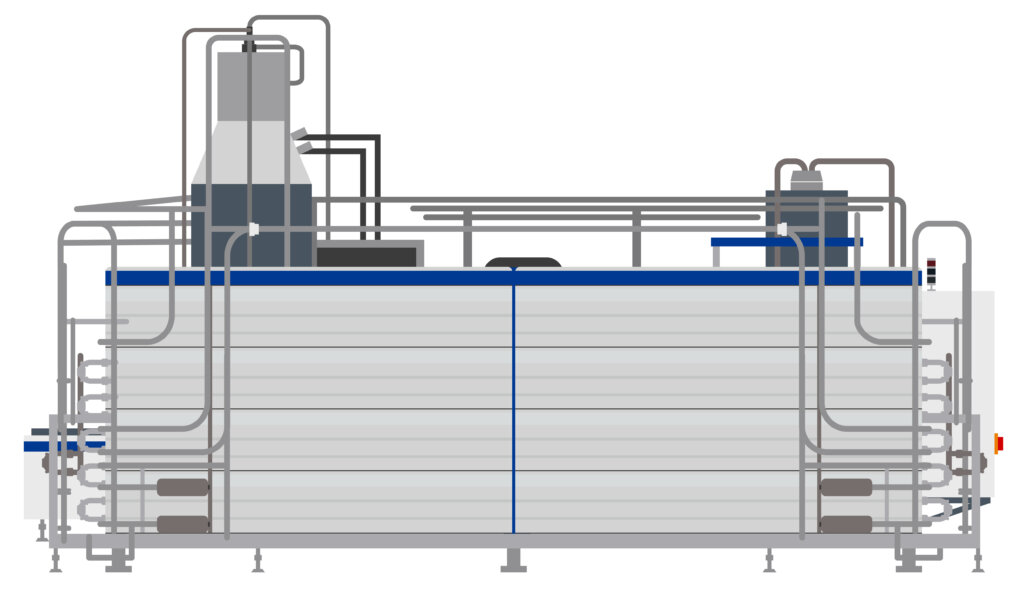

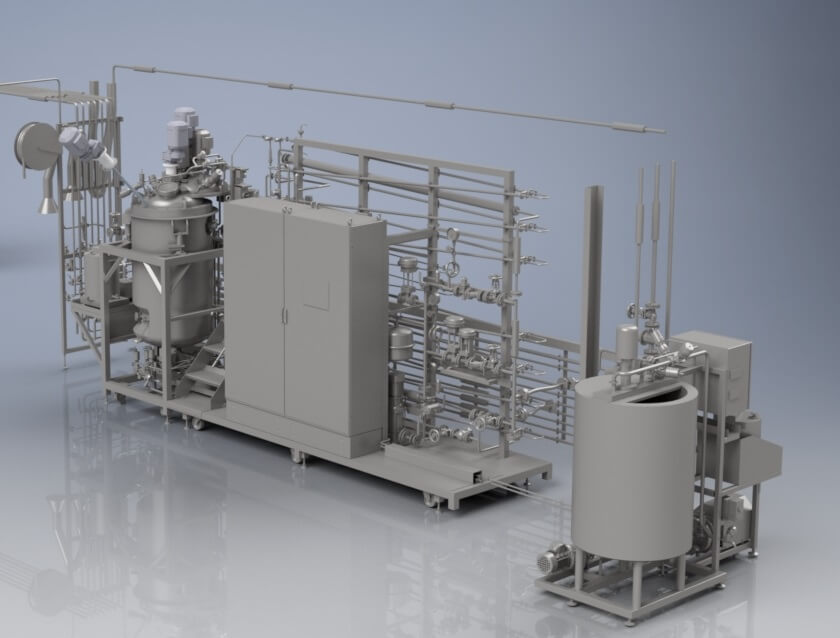

Fluidz Engineering develops and builds UHT systems. Sterilization using a UHT (Ultra High Temperature) treatment is a very short heat treatment (only a few seconds) up to a temperature of up to 140 °C. The result is a sterilized product that has a long shelf life, with minimal heat damage to the product properties.

UHT is mainly used for liquid products that need to have a long shelf life, and this technique is also used to sterilize biomass so that it can undergo a subsequent treatment.