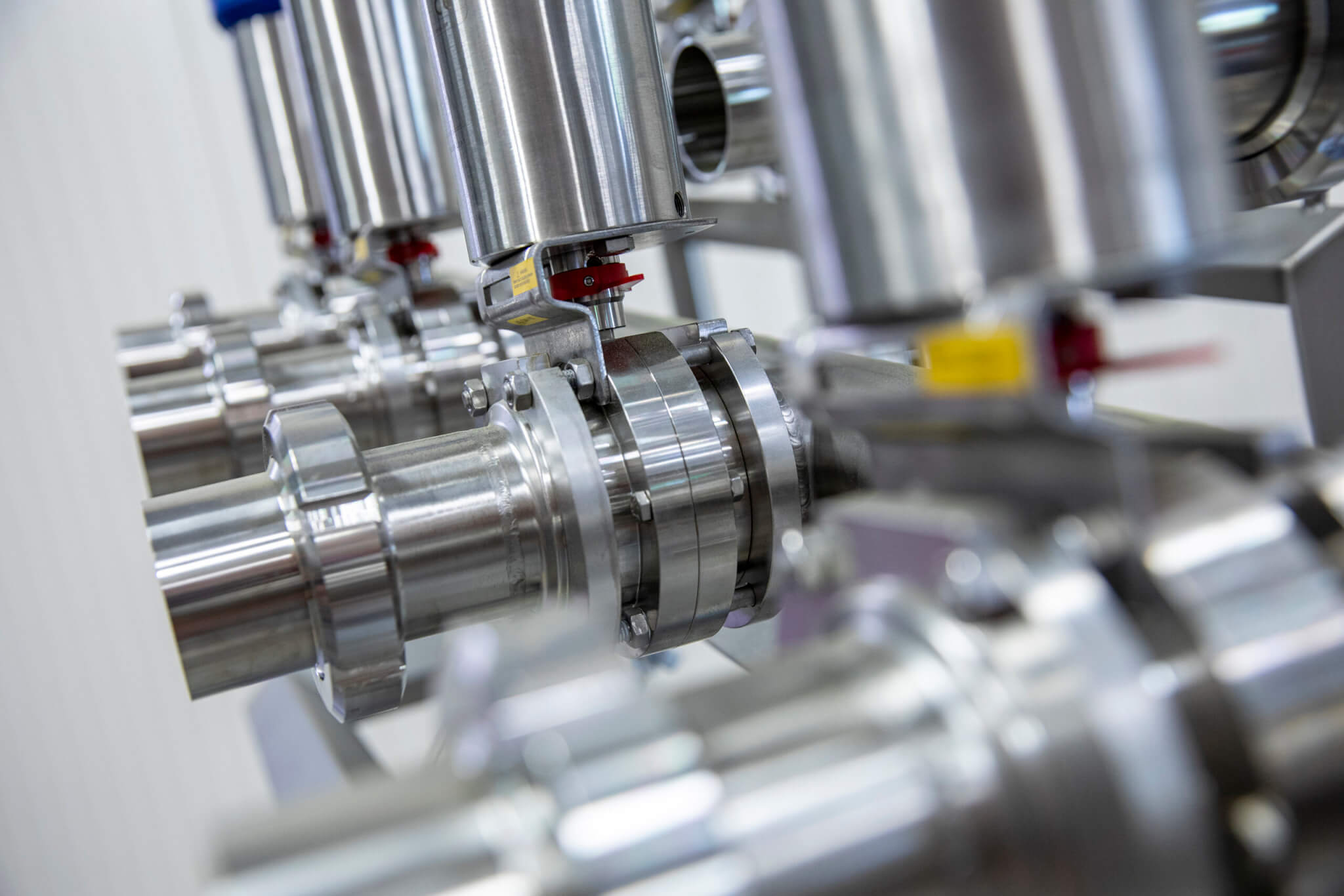

Fluid Process Experts

Where food and pharma find their flow

Do you have a company in the liquid food industry or pharmacy?

Then you have all the knowledge you need to make a good product.

Fluidz has the expertise to grow your production along with the development of your business.

Whatever your production demand is, Fluidz takes care of everything for you in the technical field.

So we are also happy to carry out maintenance!

Fluidz has all the knowledge (process engineering, mechanical engineering, electrical and control technology) under 1 roof. We can count the larger food companies among our customers and have more than 20 years of experience.

We are happy to use this experience for you as well!

You can count on us for:

Our technology supports the transition to a more sustainable production process.

More information about how we contribute to sustainable entrepreneurship can be found on the about us page.

How can we help you?

or call immediately +31 85-5001767.

Our solution is always fully tailored to your needs, without an unnecessary mountain of ‘paper’.

We like no-nonsense, are flexible, innovative with the latest technology, pragmatic and keep our promises.

We are only satisfied when our answer is a solution for you, because quality and a good customer relationship are essential to us.

Contact us and discover what Fluidz can do for you. or feel free to call us +31 85-5001767.