CIP optimalisation

In the food industry, optimizing Cleaning in Place (CIP) cleaning is critical to maintaining the highest standards of hygiene, efficiency, and sustainability. Improving CIP processes not only minimizes the risk of contamination and ensures food safety, but it also offers significant benefits in terms of energy and water reduction.

Advantages

One of the most notable benefits of optimized CIP processes is the significant reduction in energy consumption. By using advanced technologies, such as more efficient cleaners capable of cleaning lower temperatures, automated systems, and improved equipment insulation, food manufacturers can significantly reduce their energy costs. This not only contributes to cost savings but also reduces the carbon footprint of the production facility, which is essential at a time when sustainability is high on the agenda.

Saving

Another important aspect of CIP optimization is reducing water consumption. Water is a precious commodity in the food industry, and efficient CIP systems can help to minimize consumption without compromising cleaning performance. This can be achieved through the use of advanced flushing technologies, optimising flushing cycles, and reusing water where possible. By reducing water consumption, food producers can not only cut costs but also contribute to a more sustainable future.

Validation

In addition to energy and water reduction, CIP validation is an integral part of optimized cleaning processes in the food industry. CIP validation involves documenting and validating cleaning procedures to ensure that they are consistently effective. This is essential to comply with strict food safety regulations and standards. By performing CIP validation, food manufacturers can feel confident in the effectiveness of their cleaning processes and ensure regulatory compliance.

Optimization

In conclusion, optimizing CIP cleaning in the food industry offers numerous benefits, including energy and water reduction and the need for CIP validation. By investing in advanced cleaning technologies and procedures, food manufacturers can not only ensure the quality and safety of their products, but also contribute to a more sustainable future for the industry.

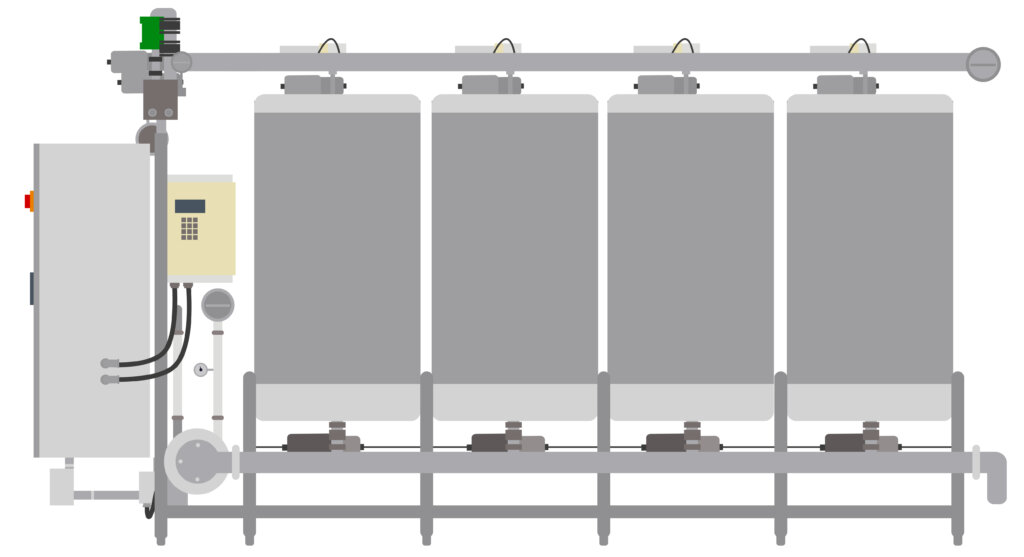

Fluidz can do an extensive examination of your CIP cleanings for you. We log all relevant data and analyse it in order to provide sound advice. This opinion includes the following:

- Optimisation of pre-rinse times, cleaning times, cut-off times, temperatures and chemical concentrations.

- Overall performance van de CIP unit

- Possible energy savings per specific cleaning

- Possible water savings per specific cleaning

- Possible chemical savings per specific cleaning

- Advice to improve the effectiveness of the CIP installation and/or objects to be cleaned

Wilt u meer weten over onze mogelijkheden op het gebied van CIP optimalisatie, neem contact op met één van onze CIP specialisten.