Very useful

“The M-CIP was, I now work elsewhere, very useful for us in the beverage preparation department. The price-productivity ratio is good, you don’t have to adjust systems, you can control a wide range of cleanings and you don’t have to be a high-tech operator to test.”

Rapidly changing market

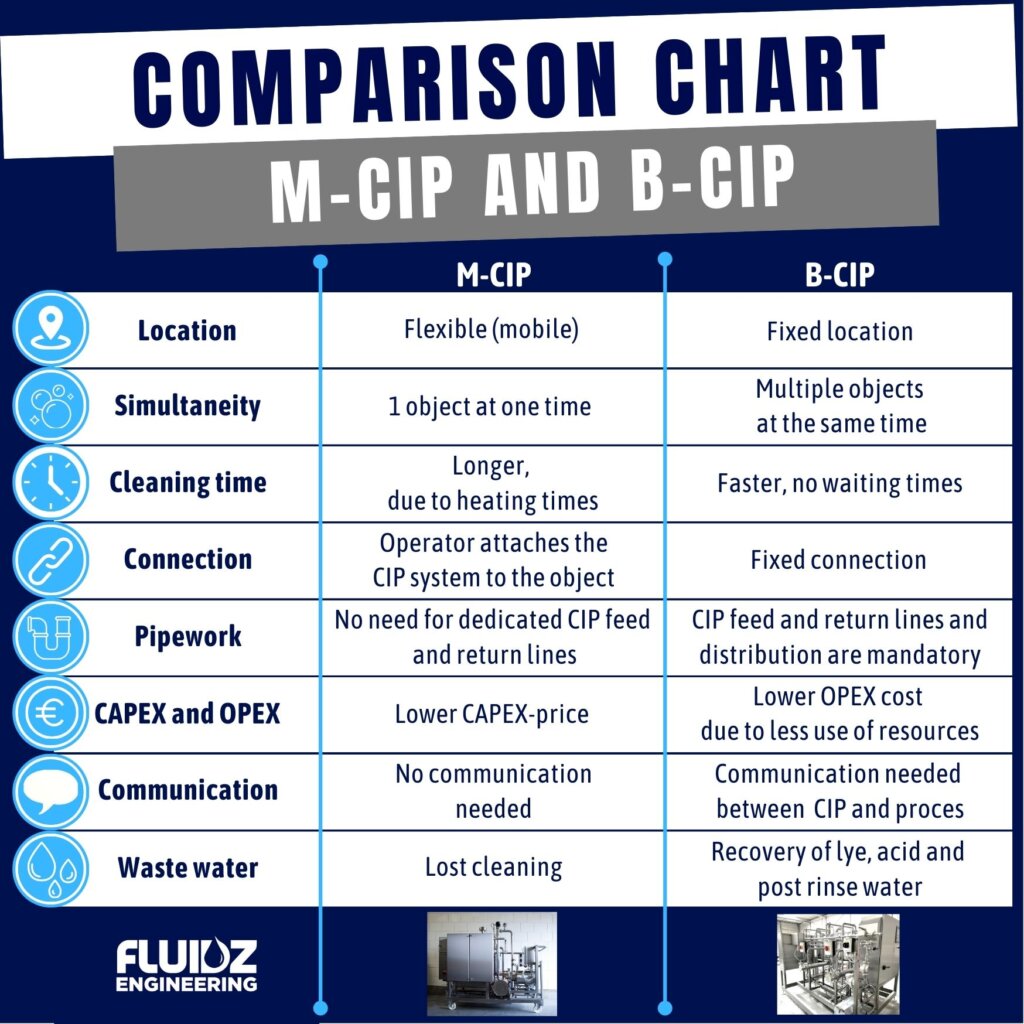

I worked at a producer for alcoholic beverages. Due to a changed mix of products, colours and lower alcohol percentages, there was insufficient natural resistance to growing micro-organisms, colour and/or flavour transfers. The tanks, pipes and machines had to be cleaned differently. The market changed so quickly, also in the CIP field. We were searching.

CIP adapted to our needs

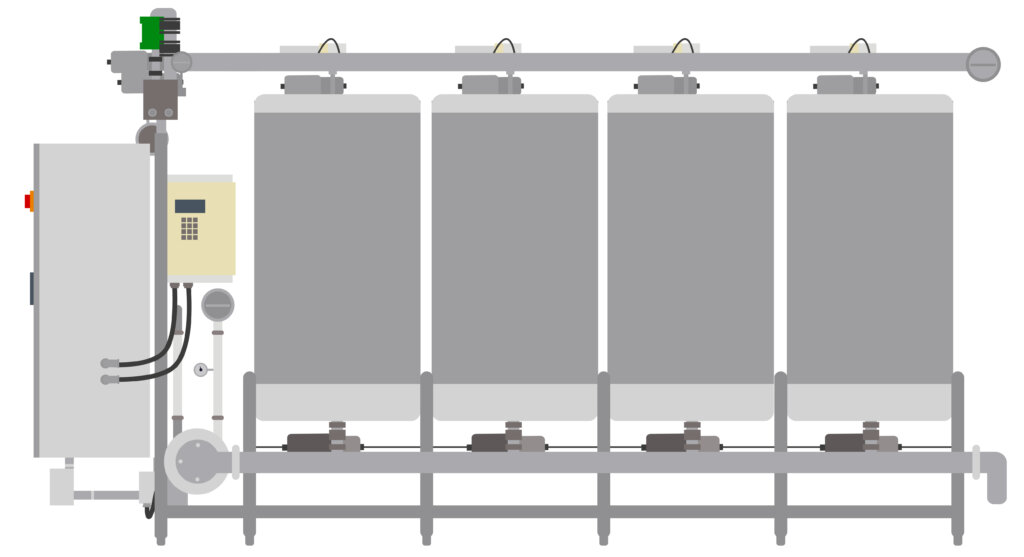

We didn’t want to immediately convert the entire factory to be able to connect everything to a complete CIP. In addition, it was too big an investment and we still had to test whether it worked. The starting point became a standard M-CIP design and with Dominique we discussed our additional wishes: choice of heating element, cleaning fluids, hot and cold water connection, etc. On location, we could try all kinds of things with valves and hoses, so that it was completely tailored to our situation. In the field, the software engineer took care of the fine tuning and we received on-the-job training. We programmed the different cleaning programs, depending on the tank size (a range of 500 to 100,000 litres) and different pipe diameters. It’s not a complicated system and as sr. operator, the basic parameters can be adjusted well.

A test in 1 day

So we didn’t know exactly what we wanted to do with the central CIP within the entire factory, which has 7 production lines, 300 tanks and more than 4000 meters of piping. With the M-CIP, we were able to see how everything reacts, what the quality is and what physical forces are at play. Of course, you want to keep the cleaning as short as possible and this was an effective and quick way. In 1 day we already had a test. This made the choice for a larger CIP much easier.

Useful for a smaller company

For a smaller company and/or if you have smaller tanks, the M-CIP is also useful. You fill it with water and a jerry can with cleaning agent, provide compressed air and then all you have to do is plug it in. You can choose different cleaning agents, with a pump and extra valve both lye and acid cleaning is possible. This makes the M-CIP extra flexible. Also literally, because his mobility is very easy. You really drive it everywhere. Last but not least: the safety of the system is fully guaranteed with all kinds of safeguards in the software but also in the hardware, so that the operator and the equipment can be operated safely.

Read more

Read less